Agronomy Update

Jul 01, 2024

Agronomy locations will be closed July 4th and 5th.

Fungicide Custom Application 2024

Conditions are favorable and the time is now to plan on a fungicide application at flowering. Horizon Resources and Aero Spray are still working close together on custom applications with Aero Spray’s use of airplanes and helicopters. Rick and Fletcher are just getting fired up and getting moving, we on the agronomy team are willing to stage your crops for flowering and will have as much fungicide we can have on hand. Fungicide is a fast-paced season and we are usually the last in line to get the fungicides everyone wants. We will bring in as much as we possibly can and will get the maps to the airplane and helicopter teams to make sure your crop is covered. Any questions feel free to call or stop in and visit with our team.Austin Semenko, Williston Agronomy Location Manager

Fungicide Selection and Timing for Head Scab

Managing head scab is all about reducing the amount of vomitoxin (VOM) in the harvested grain. The best products on the market, timed perfectly, reduce vomitoxin by 40-50% on average. In 2008, researchers pooled together data from 100 wheat studies across 11 years and 14 states and determined on average the reduction in VOM from the primary products that were on the market at the time: Prosaro, Caramba, Folicur (generic tebuconazole) and Tilt. They found that Caramba reduced VOM by 45%, Prosaro by 42%, Folicur by 23% and Tilt by 12%. Below is a table where I have calculated what the VOM would be with and without a fungicide application with these different products at 2, 5, 10 and 20 ppm VOM. Even at 5 ppm, you can see that using a product that gives you less control only reduces VOM by 1.0—0.6 ppm, which really will not improve the marketability of that crop. | Product | VOM (ppm) |

| Untreated | 2 | 5 | 10 | 20 |

| Caramba | 1.1 | 2.8 | 5.5 | 11.0 |

| Prosaro | 1.2 | 2.9 | 5.8 | 11.6 |

| Folicur | 1.5 | 3.9 | 7.7 | 15.4 |

| Tilt | 1.8 | 4.4 | 8.8 | 17.6 |

A properly timed fungicide application at the early flowering growth stage and up to one week post early flowering also protects the flag leaf, increasing yield. In a trial I conducted in 2022 at the Nesson Valley research center near Epping, which is under irrigation, the untreated check yielded 74 bu/ac, the Miravis Ace treatment yielded 100 bu/ac, Sphaerex yielded 92 bu/ac and Prosaro yielded 89 bu/ac. In that same study the untreated check had 14 ppm DON, compared to 6.7 ppm in the Miravis Ace treatment. In a highly susceptible variety of durum, yield increases of as high as 24% and VOM reduction values of up to 77% have been observed under heavy disease pressure. All that said, none of these products will work well if you do not time the application properly.

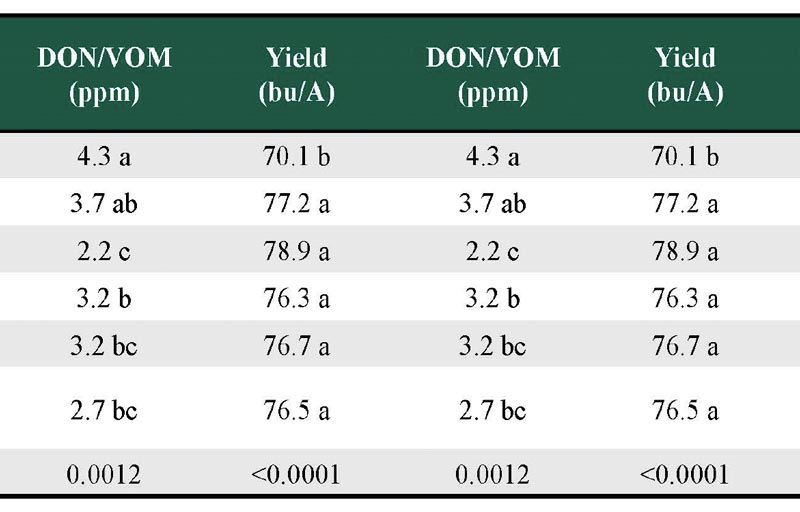

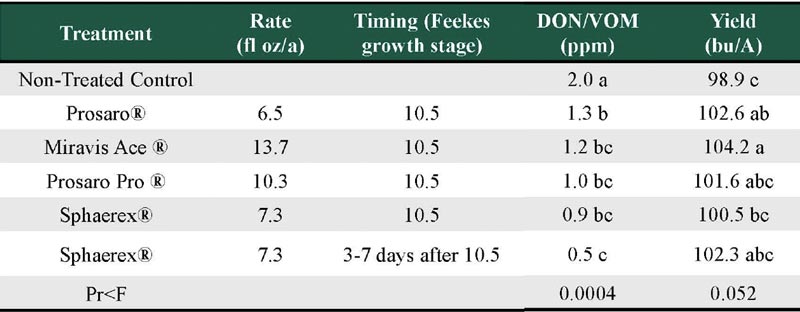

Below is a table put together by NDSU Small Grains Extension Pathologist, Dr. Andrew Friskop based on trial data from Fargo, Minot and Nesson Valley (2022 & 2023) showing the effect of a fungicide at early flowering, and for Sphaerex up to 7 days post early flowering in durum. Miravis Ace applied at flowering and Sphearex applied 3-7 days post early flowering reduced VOM the most. Miravis Ace and Prosaro also work well at that 3-7 post flowering timing based on older trial data. Yield increases from a fungicide application were 6-8 bu./ac on average.

You can see in the image above (courtesy of Dr. Friskop), what early flowering timing looks like with just a few yellow anthers around the center portion of the head. This would be on the majority of the main stems at a field level.

In Barley, the timing for a fungicide application for head scab is when the head has fully emerged from boot (Feekes 10.5 – see image below). I have been asked many times if you can apply the fungicide when the heads are in boot and the answer is NO. That fungicide must be applied to the head because that is where the pathogen infects. If you apply it in boot you will miss the head completely. At a field level where growth stages might vary, you are targeting when the majority of the crop reaches full head emergence. VOM reductions from a fungicide application in barley show a similar trend to durum. In the data generated by Dr. Friskop and his collaborators (below), Sphaerex applied 3-7 days after that Feekes 10.5 growth stage reduced VOM the most, going from 2 ppm in the untreated check, to 0.5 ppm.

A new product called Prosaro Pro 400 SC is now available from Bayer. This product adds the active ingredient Fluopyram, a Group 7 fungicide, to the existing Prosaro product which is Prothioconazole + Tebuconazole, both Group 3s. We are holding off on using Prosaro Pro in small grains until Fluopyram has been approved by our international markets, including Italy, so that we do not negatively impact the marketability of durum, spring wheat or barley grown in our region. If you have any questions on what I discussed above, feel free to reach out to our Agronomy team.

Dr. Audrey Kalil, Agronomist/Outreach Coordinator

Generics: Sometimes you get what you pay for

I had it happen again today, someone told me that they did not need a surfactant or spray adjuvant because they had bought a generic and they had some left over. There are always ways to save money, but you are counting on these products to get the active ingredients into the targeted weeds or to get coverage on the plant you want to protect from disease. The adjuvant is the doorway to eliminate weeds. If you don’t get enough of the active ingredient into the plant, you are just feeding the weed population in your field a low dose of the active which is the pathway to creating resistant weeds. With fungicides, it is critical to get good coverage, plant tissue that is not protected will be entry points for the disease. Most of the actives we are using have become generic since just about everything is post patent now and anybody can produce products with the actives along with their surfactant package. The problem with surfactants and almost all adjuvants is that they are not regulated by the EPA like the active ingredients. The difference between the generics and the parent products, for example the glyphosate products, is usually the surfactants that are being used in the products to get them into the weed. Glyphosate or Roundup products are always being kicked around with prices and when it comes down to the difference in prices, it is 100% because of the quality of the surfactants used in the products or if they even have a surfactant in them at all. This is what makes the higher end Roundup products rain fast in about 15 minutes versus up to 2 hours on some of the cheapest products. I have read labels on some of the cheapest products and since the surfactants are not regulated, I have seen the labels go as far as stating “Adding a non-ionic surfactant at the recommendation of your local consultant may increase the efficacy of this product”. So, they are just leaving it up to whomever you call your local consultant, I guess.

Anyone can make and sell adjuvants and as far as you know, they could be putting dish washing soap in a jug. If you buy an adjuvant made by a reputable company like Winfield United, CHS Inc, Wilbur Ellis, or any other major manufacturer, you will be getting products that have been tested and put into plot comparisons with competitors to make sure you see the results you need. Winfield United has an Innovation Center outside of St Paul, MN that we had a chance to tour this winter. They have made a huge investment in wind tunnels, greenhouses and laboratories to test their products and show results against all competitive products. Their chemist has found that several competitor products do not contain what they claim to. I tried to get the list of the products that they said were probably no more effective than water, but they were pretty professional about it, and I did not get the list, but we all know they are out there.

Make sure you are using high quality products made and sold by reputable manufacturers and retailers. Particularly in light of what is happening with herbicide resistance. Don’t use snake oil when we are trying to hold off resistance that is already here, and getting worse. We can do the math for you and even if you can buy an oil product for grass weed management in pulse crops at half price, it will only make the difference of $.01 to $.04 per bushel in your cost of production and that is only IF the product works exactly the same. Also, be careful with buying the least expensive fungicide available. These products are not all the same, and just because it is labeled for a crop or a disease does not mean it will work. We have issues with fungicide resistance and some products are just not good on certain diseases. We have already seen this happening this year also. Please visit one of our agronomy locations and ask our qualified staff if you have any questions. You get what you pay for, and we are not trying to sell you anything that is not agronomically sound.

John Salvevold, Agronomy Division Manager, CCA

Current Head Scab Risk

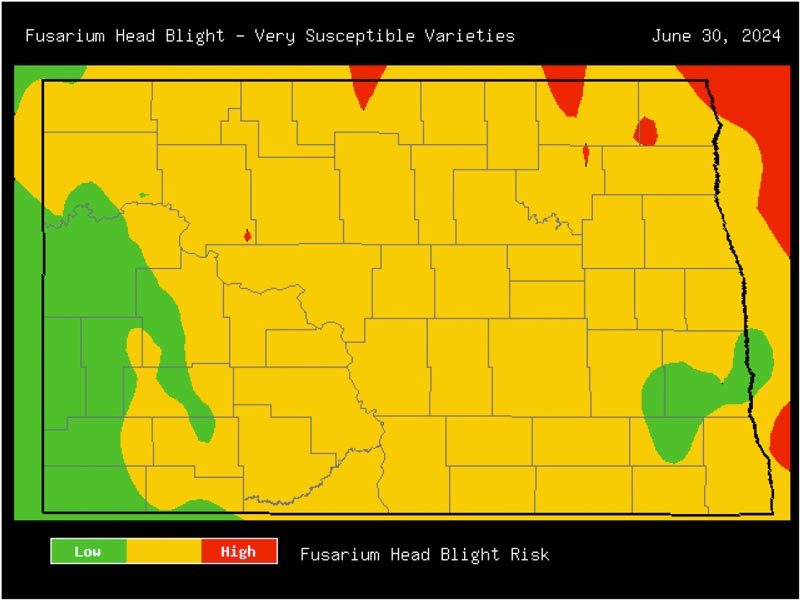

Below are the NDSU Small Grains Disease Forecasting Model scab risk map (top) and the National Fusarium Risk Tool map (bottom) for very susceptible varieties of HRSW or durum flowering June 30th or July 1st respectively. According to the National model we have significant risk across the state, while the NDSU model predicts moderate risk in many areas. Given our weather patterns I think the NDSU model is underpredicting risk for our area.

Fungicide Application Timing for Pulses

Lentils, peas and chickpeas in many fields have reached or will soon reach early flowering (R1). One lentil field I scouted last Friday had reached R2 (full bloom). With the exception of chickpea which warrants a application as soon as symptoms are observed, we usually want to target the fungicides at bloom just prior to canopy closure. We are either at or getting close to that point and with the cool, wet weather we are at risk for several foliar diseases including Ascochyta, Anthracnose (lentil) and White Mold (lentil). Fungicide resistance to the Group 11 chemistries has been documented in Ascochyta of chickpea and pea in North Dakota which narrows the options for effective fungicides. Make sure you are picking a product that will be effective for the pathogen you want to control and be aware that a “one size fits all” approach will not work. If you have any questions please feel free to reach out.Dr. Audrey Kalil, Agronomist/Outreach Coordinator

Enhancing Wheat Protein

Small grains have been getting what they need this year with timely rains and favorable weather. On top of our optimal growing conditions, I’ve received a lot of calls about timing fungicide for head scab in wheat and durum this week. All the indicators are popping up mentally for me that this crop could be above average for our area, and usually with above average yields come below average quality, namely protein content. If you are looking to be proactive and try to enhance your protein content in grain, there is one last ditch effort you can make to bump protein content by 0.5 to 1%. That is to apply 30 units of nitrogen via 28% UAN post anthesis. This is most done with 10 gallons of 28% UAN + 10 gallons of water applied with flat fan nozzles (not streamer nozzles) at a total volume of 20 GPA just after the wheat or durum is finished flowering. This mixture does leave some leaf burning but I’ve seen this done countless times and it has never impacted yield. If crop response is of a concern, applying it in early mornings or late evening when dew have set in will alleviate leaf burn.

Realistically it would be logistically difficult to apply to an entire crop with this mix in a timely fashion. Instead, take a systematic approach; target fields planted to the higher yield varieties (which are typically lower protein) and choose your earliest planted fields (which are usually your highest yields) to go to first and apply 30 units N post anthesis to bump protein.

Kyle Okke, Crop Consultant, CCA