Agronomy Update

Feb 10, 2025

MonDak Pulse Day—February 26th

MonDak Pulse Day has been scheduled for Wednesday February 26th at the Grand Williston Hotel and Conference Center. The agenda features weed, disease and agronomic management to maximize your pulse production.Registration will be via NDSU Extension. The speaking agenda is below:

Dr. Brian Jenks, NDSU: 2025 Weed Control Update

Dr. Michael Wunsch, NDSU: Improving Root Rot and Foliar Disease Management

Kyle Okke, Agile Agronomy: Weed Management Strategies for Field Pea and Chickpea

Jesse Lacock, Corteva: Rotating Cereal Crop Protection

Dr. Bill Franck, MSU: Pulse Variety Update

Mickie Dent, CHS: Pulse Market Update

2024 Durum and Spring Wheat Quality

In the Horizon Resources trade area, we experienced a range of growing conditions for both durum and spring wheat this season. Spotty rainfall, coupled with heat following the 4th of July, led to significant variability in both yield and quality across the region. Yields ranged from 20 to 80 bushels per acre for both durum and spring wheat.Starting with durum, areas to the south and west of Williston saw lighter test weights, with some of the lowest weights between 52 to 54 lbs. However, the amount of crop at those lower test weights was less than anticipated. In contrast, regions to the north and east of Williston, including Alamo, Grenora, and Zahl, experienced test weights above 60 lbs. The average protein content for durum was 14%, with color averaging around 85 HVAC, which can be attributed to the dryness and stress the crop endured in July. Despite initial concerns about vomitoxin (VOM) due to the wet conditions in June and early July, the levels of VOM in the durum we shipped remained well below 0.5 ppm. Timely fungicide applications and lack of rainfall in mid and late July suppressed disease development and contributed to maintaining low VOM levels.

For spring wheat, yields followed a similar pattern to durum, with a high degree of variability depending on field location. Protein content fluctuated between 11% and 16%, with the overall average in our trade area of around 14%. VOM levels and test weights were similar to durum.

The North Dakota Wheat Commission assembles statewide quality data for durum and spring wheat, based on grain samples submitted through Extension Agents and grain elevators. You can view the 2024 reports on their website. For durum, DON was higher and protein was lower in 2023 compared to 2024, however, test weights were similar across years. DON was also detected in HRSW in 2024, compared to non-detectable levels in 2023. Spring wheat test weights and protein were similar across the two years. Based on the data they gathered on durum and wheat quality, the ND wheat commission has published a wheat variety selection guide to help our region maintain access to premium markets.

Ethan Klundt, Grain Merchandiser

Legume Nitrogen Fixation and Inoculation

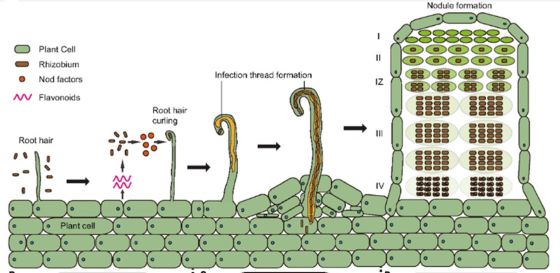

Leguminous crops such as peas, lentils, chickpeas and soybeans have the ability to access nitrogen from the atmosphere through the symbiotic relationship they form with rhizobia bacteria. Termed “biological nitrogen fixation,” this relationship is mutually beneficial, where the bacterium receives carbon sugars from the plant in return for the nitrogen. Root nodules (image below) are plant structures which house the rhizobia, the formation of which is triggered by a chemical exchange between the host plant and the rhizobia. The plant roots release flavonoids that are detected by the rhizobia in the soil, who in turn produce Nod factors. Once the plant detects these Nod factors the symbiosis is initiated through the root hairs. This chemical dialogue lets the plant know that the bacterium is not a pathogen, and so the plant allows the bacteria to enter and begins to form the nodule around it (diagram below).

The blend of Nod factors used to communicate with the plant host are unique to rhizobia species, and this is why the plant-rhizobia relationship is so specific. When growing a legume crop for the first time, inoculation is critical because these specific rhizobia may or may or may not be in the soil. We continue to inoculate in these fields to ensure that we establish good nodulation. Below is a table of the rhizobia species that are used in commercial inoculants to nodulate the legumes that we grow. Note that the rhizobia species are the same for peas and lentils. There are granular inoculant products on the market now that blend together the pea, lentil and chickpea rhizobia for added convenience.

| Crop | Rhizobia Species |

| Pea/Lentil | Rhizobium leguminosarum bv viciae |

| Chickpea | Mesorhizobium ciceri |

| Soybean |

Bradyrhizobium japonicum Bradyrhizobium elkanii |

| Dry bean |

Rhizobium leguminosarum bv phaseoli Rhizobium tropici |

| Alfalfa | Sinorhizobium meliloti |

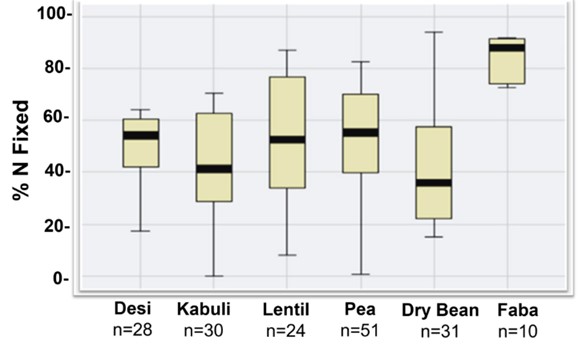

Nitrogen fixation has been measured for different leguminous crops (graph below). The thick black line inside the box is the average level of fixation, but the tan boxes and lines coming off of the boxes show the entire range of fixation that occurred. Overall there was a lot of variability. Nitrogen fixation is affected by many factors including plant genetics, soil quality, soil N levels and environmental conditions. The legume crop you are growing has the potential to fix a certain amount of nitrogen but the amount fixed will be impacted by good inoculation practices and managing soil conditions that could negatively impact nodulation. In the future, variety selection could be important as well. In one study, researchers found that percent N fixed varied from 5 to 78% among the 12 dry bean lines that were evaluated.

Drought conditions negatively impact nitrogen fixation by disrupting the chemical signaling steps that lead to the formation of the symbiosis and the exchange of carbon for nitrogen. While we can’t control the weather, research at the Agriculture and Agri-Food Canada (AAFC) Indian Head and Melfort locations on field pea found that granular performed better than peat, which in turn performed better than liquid when soil moisture conditions were below normal. This may be due to enhanced rhizobial survival when applied in this stabilized medium. Nodules are formed close to where the rhizobia bacteria are placed, so it is important for a granular inoculant to be applied at the correct rate across a field so the bacteria can come in contact with the germinating seedling. The advantage of peat and liquid inoculants are that they are in direct contact with the seed.

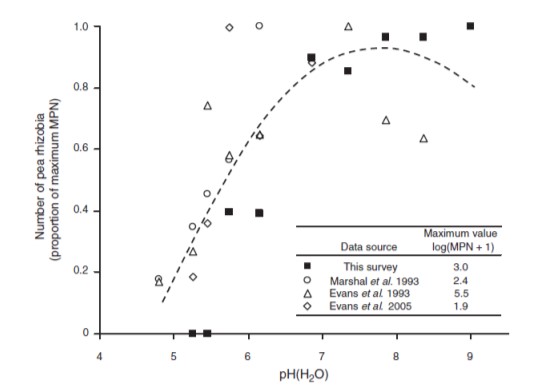

Low soil pH also reduces nodulation as well as survival of rhizobia in the soil. Under these conditions inoculation is going to be particularly important as less rhizobia will be present in the soil from previous host crops. The chart below is from research conducted in Australia and shows the relationship between soil pH and the number of rhizobia in the soil capable of nodulating pea. As the soil pH drops so does the rhizobia population, particularly below 5. These researchers concluded that inoculation of pea is likely to be beneficial where the soil pH was below 6.6, particularly if summers have been hot/dry and it has been five years or longer since a host crop.

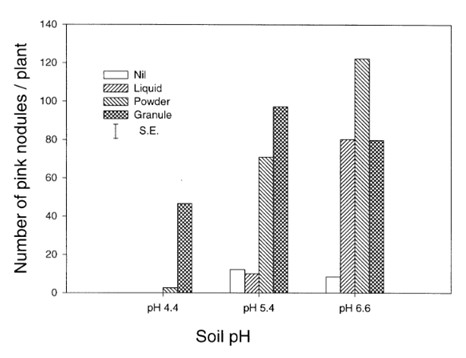

Research by Rice and colleagues at AAFC in Alberta, CA found that at lower soil pH, the granular inoculant formulation resulted in higher nodulation of pea compared to peat powder or liquid under greenhouse conditions (chart below).

Granular inoculant formulations may provide an advantage in situations where survival of the rhizobia is compromised either by drought or acid soils because that formulation provides more protection for the rhizobia bacteria. With a liquid inoculant the bacteria is more exposed to stressful conditions on the seed and in dry soils.This demonstrates why it is important to store and handle all inoculant products and formulations with care. Product that is over heated or frozen, for example, will not give you the same benefit as inoculant that has been stored properly.

Dr. Audrey Kalil, Agronomist/Outreach Coordinator

Purchase Inoculants with Returns in Mind

As growers are getting acres figured out for pulse crops for 2025 and placing orders for inoculants, it is important to plan carefully and not buy more than you need. Please keep in mind these return policies on inoculants and how this affects both of us.In past years, especially before 2011, most inoculant manufacturers did not take back any inoculants and were very strict on this policy. In 2011 we had a very wet spring, and there were many acres that did not get planted. With the amount of pulse crops in North Dakota and Montana, dealers and growers were sitting on possibly millions of dol- lars’ worth of inoculants on these acres. This put a lot of pressure on these companies, and they changed the policy on returns and took back most of their products that spring. Since then, some companies continue to offer limited returns that are usually a small percentage of our purchases, but no more than 15%.

Inoculants are a living organism, so when we do get any of these prod- ucts returned to us, we will keep them separated on a non-sale basis and we plan on returning them to our supplier. Once they leave our facility at the time of sale, we have no control over what kind of envi- ronment you keep them in, and we have no way to guarantee that the inoculants that you are returning are still alive. I always use the exam- ple of a box of sterile peat inoculant that is pretty light and can easily ride inside the cab of a truck. If you have a really hot spring day, the temperature inside the cab can get pretty hot and could possibly kill that inoculant. If we take this inoculant back from this person and send it out with the next customer, that customer will not be really happy when he does not get any nodulation with the dead inoculant. Worse case scenario, lawsuits can/have happened dragging the previous pur- chaser and/or seller into liability for a crop failure.

For that reason, we will have to limit returns to the same return limits as our suppliers, and anything that ends up back at our warehouses has a deadline for us to return to distribution, which is usually around the middle of June. If you bring back an inoculant in August or later and we are beyond our return deadline, and you will be turned down since there is no opportunity for us to get our money back at this point. In fact, whatever we end up with in our inventory at the end of the year is destroyed and basically thrown in the garbage as a total loss of the entire cost of inventory.

Please work with us to limit any returns of inoculants so we can try to keep our losses to a minimum. We will normally have something available during the spring within our company if you need a little extra to finish seeding, so don’t feel you need to over order then return if you don’t use it.

John Salvevold, Agronomy Division Manager, CCA

Changes to Express(R) Label

Over the past year, the Express® Herbicide with TotalSol® Granules label has been updated to allow for a 1-day plant back interval to most pulse crops when used at 0.25oz/A in a burndown application. This now mirrors the Canadian version of this label which has allowed for a 1-day plant back to these crops for many years. Crops in our area that this application will be safe on and benefit from will be primarily field peas and chickpeas. Larger seed size and deeper planting of field peas and chickpeas versus other pulse crops allows for Express® Herbicide to be safely used at the shorter plant back interval in NW ND/NE MT. We do need to be careful with lentils and stay at a 7-day plant back with Express® Herbicide, especially when our pH is 7.9 or greater. The added benefit of the 1-day plant back interval of 0.25oz/A of Express® Herbicide in front of both field peas and chickpeas will primarily be seen as a wider application window for the burndown application as well as an excellent option to burndown troublesome weeds such as narrowleaf hawksbeard, prickly lettuce and canola while also increasing burndown activity on Canada thistle and dandelions.Ryan Hunt , Technical Service Manager ND/SD, FMC Corporation

Using MOA, SOA, & Chemical Families to your Advantage

As time goes on, the number of weeds developing herbicide resistance will only continue to grow. It’s an unfortunate reality with the limited number of herbicides we have available to us, and to compound the issue, new MOA’s & SOA’s are not a fast-developing pipeline. I’m not writing this to you as a “doom & gloom” type message but more of a “reality check” to make sure we are aware of our situa- tion and how we deal with it.

To manage herbicide resistance, we must first understand MOA, SOA, and Chemical Families

MOA = Mode of Action

SOA = Site of Action

Simply put, MOA is how the herbicide works, SOA is where the herbicide goes to work and within each SOA there are different chemical families. The numbering system you see on chemical labels and other places like the NDSU weed control guide are depicting the SOA. If you page through the NDSU weed control guide to pages 98 & 99 you will see a comprehensive list of SOA, but you will also see the chemical families within each SOA.

OK, let’s put this in terms that are easier to follow and talk about mechanics and how this can relate to MOA, SOA, & chemical families.

Example: you bring your vehicle to the mechanic when it breaks down, the mechanic says you have a fuel system issue, that’s the MOA. But the fuel system issue is a vague description, when asking more specifically the mechanic says you have plugged fuel injectors, that’s the SOA. When your mechanic asks if you want to clean or replace those fuel injectors, that’s like choosing chemical families.

To reiterate, SOA is specifically where things work, but you can choose different chemical families within the same SOA and get different results. Like the example above with plugged fuel injectors, both cleaning and replacing fuel injectors work, you just might get more miles out of one vs the other. To the farmers who understand mechanics better than I do, don’t chastise me, I’m an agronomist first. But hopefully you get my point!

Back to a real scenario. Some of you deal with foxtails that are re- sistant to the Group 1 SOA, and here is how it can happen. Durum and pulse crops are a pretty common rotation for us.

For some farms the rotation follows as such:

Season 1: Durum

Season 2: Durum

Season 3: Lentil

Season 4: Durum

Season 5: Durum

Season 6: Field Pea

For that rotation, the following chemicals are applied in season for foxtail control:

Season 1: Durum – Discover

Season 2: Durum – Puma

Season 3: Lentil – Assure II

Season 4: Durum – Discover

Season 5: Durum – Puma

Season 6: Field Pea – Targa

Lets break these products down into active ingredients and SOA:

Season 1: Durum – Discover (Clodinafop, Group 1)

Season 2: Durum – Puma (Fenoxaprop, Group 1)

Season 3: Lentil – Assure II (Quizalofop, Group 1)

Season 4: Durum – Discover (Clodinafop, Group 1)

Season 5: Durum – Parity (Fenoxaprop, Group 1)

Season 6: Field Pea – Targa (Quizalofop, Group 1)

Now before I break into chemical families, lets visit page 98 of the NDSU Weed Control guide:

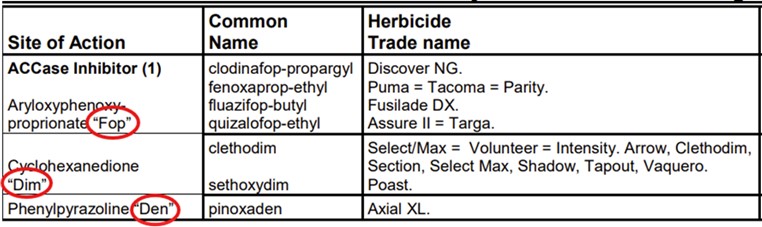

I clipped out the contents from Group 1 SOA. See how you have different active ingredients listed in each row? Now look where the words FOP, DIM, & DEN are circled. Those are the nicknames for the different respective chemical families from the group 1 SOA. OK, back to the rotation scenario..

Rotation break down of products into active ingredients, SOA, & chemical family.

Season 1: Durum – Discover (Clodinafop, Group 1) FOP

Season 2: Durum – Puma (Fenoxaprop, Group 1) FOP

Season 3: Lentil – Assure II (Quizalofop, Group 1) FOP

Season 4: Durum – Discover (Clodinafop, Group 1) FOP

Season 5: Durum – Parity (Fenoxaprop, Group 1) FOP

Season 6: Field Pea – Targa (Quizalofop, Group 1) FOP

So, as I kept breaking things down, you can see that while the chemical brand names were different every year, the actual active ingredients were used more than once, and if you look at the chemical families, you didn’t change at all. So, these foxtail populations have been hit with the same exact same SOA and chemical family for several years. If you keep pounding a weed repeatedly with the same tool, I promise you mother nature will find a way to overcome it, and it has for some, unfortunately.

A better step would be to rotate SOA and chemical families to ensure a different approach to the foxtail population:

Season 1: Durum – Everest 3.0 (Flucarbazone, Group 2) Triazolinone

Season 2: Durum – Puma (Fenoxaprop , Group 1) FOP

Season 3: Lentil – Section Three (Clethodim, Group 1) DIM

Season 4: Durum – Discover (Clodinafop, Group 1) FOP

Season 5: Durum – Opensky (Pyroxsulam , Group 2) Type 2 - TPS

Season 6 : Field Pea – Section Three (Clethodim, Group 1) DIM

This example of rotating SOA and chemical family will slow down herbicide resistance, but you are still relying heavily on only two SOA’s. A better way to tackle this is to add another crop into rotation to allow more MOA’s into your rotation.

Season 1: Durum – Everest 3.0 (Flucarbazone, Group 2) Triazolinone

Season 2: Durum – Puma (Fenoxaprop, Group 1) FOP

Season 3: RR Canola – Cornerstone 5+ (Glyphosate, Group 9)

Season 4: Durum – Discover (Clodinafop, Group 1) FOP

Season 5: Durum – Opensky (Pyroxsulam, Group 2) Type 2 - TPS

Season 6: Field Pea – Section Three (Clethodim, Group 1) DIM

Adding a crop like Canola into your rotation will bring a whole new SOA that foxtail doesn’t see during the growing season (Group 9). Not only will this bring a new SOA but it brings a new timing that the herbicide gets applied and a crop that is rather aggressive at shading out the ground, preventing new seeds from germinating.

For those of you that have kept with me this far, there is one other mode of action not mentioned that has activity on foxtails (some labeled with control, some just suppression and some not labeled). That’s the HPPD inhibitors (Group 27). Tolvera is a new product available for commercial use this year in wheat and durum (NOT a new SOA or chemistry). BUT it has labeled activity on green foxtail and is a 9-month rotation interval to peas and lentil (BIG deal for us!).

The other small grains products like Talinor and Huskie that contain a Group 27 SOA don’t list control of grasses like foxtail, but trust me they are doing something. They can’t be relied upon by themselves so you need to pick a group 1 or 2 SOA grass chemistry to pair with it, but they are aiding in grass control with those chemistries so you should include them. Why you aren’t likely to use Talinor or Huskie is because they come with baggage - an 18-month rotation restriction to peas and lentils. I would encourage you to not let this keep you from using them.

Here is my final suggested herbicide rotation to use everything to your advantage to combat herbicide resistance in foxtails.

Season 1: Durum – Wolverine Advanced (Group 1 + Group 27)

Season 2: Durum – Opensky + Tolvera (Group 2 + Group 27)

Season 3: RR Canola – Cornerstone 5+ (Glyphosate - Group 9)

Season 4: Durum – Discover + Talinor (Group 1 + Group 27)

Season 5: Durum – Opensky + Tolvera (Group 2 + Group 27)

Season 6: Field Pea – Section Three (Clethodim - Group 1)

Now you are effectively rotating as much as you possibly can with SOA’s and chemical families. This gets complicated fast (which is why you have probably rolled your eyes at me more than once reading through this), but this is how you combat weed resistance, by throwing different SOA’s and chemical families each year so it’s harder for weeds to develop resistance to any single herbicide.

If you are using the KISS (Keep It Simple Stupid) method to your herbicide program because you want an open rotation to pulse crops, I promise you that weeds find their ways to overcome your herbicide program very fast. You need to complicate things, and to do so you must know the details explained above. If you complicate things, you need to keep good records to know where you put what and when.

This is why you rely on your agronomist at Horizon Resources for help, and why they use tools like Farm QA to keep records. Just one step in weed control can become complicated very quickly, and the agronomists here know how to navigate rotation of herbicide SOA and have the tools to help you quickly and easily.

Kyle Okke, Crop Consultant , CCA

Save the Date for these Upcoming Events

February 25, 2025 at 12 PM MT; Disease Management in Irrigated Legume Crops; Eastern Ag Research Center, Sidney MTFebruary 26, 2025 MonDak Pulse Day; Grand Hotel, Williston ND

March 6 - 7, 2025 Western Crop and Pest School; Bismarck, ND

March 13, 2025 Getting it Right Canola Production; Virtual