Agronomy Update

Apr 14, 2025

The Horizon Resources Annual Meeting will be held on Wednesday, April 16 at 2:00 p.m. at the NDSU Williston Research Extension Center — 14120 Hwy 2, Williston, ND. This is your opportunity to hear updates, connect with fellow members, and take part in the future of your cooperative. All members of the cooperative are invited to

attend.

Hay, Grazing, CRP, Reclamation and More: Choosing a Grass Species or Mix that Fits Your Needs

As we head into the 2025 season, I am getting some questions about the different forage and grass species and mixes offered by Horizon Resources. I wanted to take the time to address some of these commonly asked questions so you can plant the right species or mix to suit your needs. Horizon Resources is your exclusive local retailer for Buffalo Brand Seed which sells a huge variety of alfalfa, native grasses, forage grasses, cover crops and more. Buffalo Brand Seed is an independently owned seed company formed by individuals with decades of experience in the forage business and, simply put, they are THE grass experts.So let’s get down to the FAQs. First off, if this planting is for CRP purposes then it is critical that we follow the guidelines in your contract. When you come into your Horizon Resources location or call me directly, have that contract in hand so that we can make sure that whatever you plant will meet those requirements. For example, if you have a bid for cool season grasses then you are looking at the intermediate or pubescent wheatgrasses. If it is for warm season grasses then you would be looking at blue grama or western wheatgrass. Whatever your needs, we can make a custom mix for you that fits your contract.

For reclamation purposes we have the North Dakota State Land mix which is a blend of warm season native species suited for western North Dakota and Eastern Montana. That includes western wheatgrass, slender wheatgrass, green needlegrass and sideoats grama which are all native to this region. An annual grain type tame oat is included as a nurse crop because these warm season species take time to get established. They are sold in one-acre bags for convenience and have enough pure live seed in the bag for the acre if you drill it in. If you broadcast it then NDSU recommendations are to double the seeding rate, and then we recommend rolling or harrowing to improve seed to soil contact. This mix is also a great choice for folks looking to plant an area of their property to native prairie so they don’t have to mow or manage it. If you are looking to get closer to native prairie with this blend you can add 3-5 lb./ac of a native clover or a vetch.

If your goal is to establish pastureland for grazing in western ND and eastern MT then the Dryland Pasture mix was designed for that purpose. Made up of cool season grasses like pubescent wheatgrass, forage perennial ryegrass, profile orchardgrass, smooth brome (image below) and intermediate wheatgrass. The seeding rate for this mix is 10-15 lb/ac and it is sold in 50 lb bags. As with the ND State Land Mix you’ll want to double the seeding rate if broadcasting. Given our short growing season, we want to stick with the cool season species like wheatgrass, brome and ryegrass. It is important to choose a blend that was designed for our region because there are many grasses available to areas further south and those mixes will not perform well here. This mix of cool season grasses can be planted early, get established and then survive the heat of July and August. Warm season grasses will want to grow actively in those months, and we typically don’t get the rainfall to support that.

Usually, we want the flexibility of haying and grazing and at the end of the day it’s about giving the livestock the nutrition that they need. To improve the quality of the hay, I would recommend adding in at most 25% alfalfa to that dryland pasture mix. The alfalfa feeds the soil through nitrogen fixation and will increase the protein and quality of the hay. I don’t recommend going over 25% alfalfa due to the risk of bloat and the fact that it can crowd out other species. You will have to take precautions to prevent bloat when you go to graze it in the fall.

We also have several options for individuals wishing to grow an annual forage for hay or grazing. For the cool season annual forages we have Haymaker barley and several varieties of forage oats. My personal preference is for the hay barley because it gives us a little more flexibility in when we cut and bale it. If we get to it a bit later than we ideally should, it retains more palatability compared to a forage oat. The advantage of the forage oat is generally its high yield. If you want to boost the protein of this mix you can add forage peas, however, if you grow peas or lentils in that field for grain then you won’t want to go that route. We do have to seed these similar to when you would plant an oat or barley crop so the planting timing might compete with when you are planting your other crops. They like to be planted at soil temps around 45 degrees and 1.5 to 2 inches deep.

Warm-season annual forages are typically planted in response to concerns about hay shortages during drought. While we’ve had some rain this weekend and remain optimistic, the lack of snowfall this winter has many folks considering this option. Our go to forages for this purpose are the millets and sorghum x sudan hybrids. The two millet species that work best up here are German or Siberian foxtail millets. We seed these at 20 lb./ac dryland at about a one-inch depth. This needs to be planted after the risk of frost has passed, so after May 15th and ideally early June.

Sorghum x sudan is a cross between sorghum and sudangrass. This hybrid provides consistency in vigor, yield, and sweetness—livestock really enjoy it, and our variety “Buffalo Honey” is aptly named. We also carry a BMR (Brown Mid-Rib) type, which is more palatable and easier to digest due to reduced lignin in the plant cell walls. The trade-off is that BMR types are more prone to lodging, but timely cutting should prevent that. Sorghum x sudan is planted at a rate of 25 lb./ac on dryland and 35 lb./ac on irrigated ground. The ground temps at seeding should be 65 degrees or greater and like millet be past the frost-free period. Plant at one inch depth. Sorghum x sudan can be hayed or grazed, but when grazing you need to be aware of prussic acid which is toxic to livestock. Prussic acid tends to accumulate after a light frost or when it is under drought stress. Do not graze the sorghum x sudan until the regrowth reaches a minimum of 20 inches tall. If in doubt, a tissue test can confirm safety. High levels of nitrogen fertilizer or manure increases the risk of prussic acid accumulation. Prussic acid is not an issue in the plant material cut for hay as the acid degrades during the curing process. Always check for nitrate levels in your hay regardless of the hay crop type.

If you’re debating between planting sorghum x sudan or millet, each has its pros and cons. Sorghum x sudan has a deeper root system and doesn’t make the most of light surface rains. Millet, being a shallow-rooted relative of pigeon grass, is better at scavenging surface moisture. However, with good moisture availability, sorghum x sudan will typically outproduce millet.

We carry many of the species and mixes described in the article during the growing season but if you have a large order call ahead so we can make sure we have what you need in stock. If you need a custom blend call for a quote and expect the turnaround time to be about 8-10 business days. Feel to reach out to me or your local Horizon Resources location with any questions.

Gerald Halvorson, Buffalo Brand Seed

(701) 570-3452

Be Aware of Rotation Restrictions for Crop Protection Products

Over the winter and as we head into the spring planting season, we have been having conversations with customers centered around herbicide rotation restrictions—and with good reason. Whether we're talking about products applied in the 2024 crop season or residuals from last fall, understanding these restrictions is vital for crop safety, particularly with our pulse crops, and lentils specifically. With a good crop rotation and record keeping, we can minimize damage from these issues.One thing we want to avoid is selecting herbicides in our small grains so that we always have options open for lentils the following year. This is just painting yourself into a corner with herbicide use and as expected we have used up most of these products that fit this bill. If we continue to operate this way then every new product that comes our way will get burned up from resistance within a handful of years. With as limited as we are already, this is just not sustainable if we want to be growing pulse crops long term. Pulse crops should really be used in at least a 4-year rotation and ideally even longer. Some growers are finding out that 2 to 3-year rotations have promoted a lot of root diseases including Aphanomyces root rot which can stay in the soil for a decade or more.

Pre-Plant Products for Pulse Crops

We have seen some crop damage or crop response in lentils after us- ing some of the preplant products like Sharpen and even flumioxazin products (ex. Valor) depending on the rate and timing of application. Whether or not you see damage from these products will depend on the soil textures, organic matter and rainfall after these products have been applied. Usually, we expect to see the crop grow out of this type of damage. With pulse crops, we don’t have many options for weed control, and we rely heavily on these products to provide a baseline of weed control as we can do very little else in crop for weeds. For lentils, the use rate on Sharpen is such a small amount that you should not expect very long residual weed control. The flumi products must be fall applied and the rate will be dependent on the time of spraying or months before planting. Spartan is not labeled for lentils, and you real- ly need to be careful even a year ahead of lentils if you used Spartan on flax or safflower as you can still see damage a year later (below).

Herbicide injury in lentils can look a lot like root rot, so it is important to diagnose the issue instead of making assumptions.

In Crop Cereal and Canola Products

Clopyralid containing products (e.g. Stinger) used in cereal crops and canola for management of tough to control broadleaf weeds will keep you out of pulse crops for two years. If you do make the mistake of planting into clopyralid the next year, the injury will be obvious, and costly.

Talinor, Huskie products, and Pixxaro, to name a few, are some other products we use in cereals with rotation restrictions to pulses. We need all these products for resistance management, and we also need them to manage specific weed problems like Canada thistle, narrowleaf hawksbeard, marestail and large wild buckwheat.

Everest 3.0, while highly effective on green foxtail, also limits pulse op- tions the following year and this makes growers reluctant to use it. The problem that results from avoiding certain products is that now we have been spraying weaker group 2 herbicides for green foxtail man- agement, which increases the speed at which resistance develops. In some cases we have complete resistance to group 2 grass herbicides in addition to the group 1 resistance we already had.

We have a new Group 27 grass herbicide called Tolvera that is good on green and yellow foxtail but does not do well with wild oats. Growers will need to be careful with this product and it will be quite expensive if you tank mix for wild oats. It has not taken very long to develop resistance to the Group 1 and Group 2 grass herbicides so please be careful with your rates and with your water volumes and include the necessary adjuvants depending on your mix. You want 100% weed control with this and if you do not get it, the weeds that make it through will develop a tolerance and the offspring of those weeds could be resistant to this. That is how fast this can happen, so be careful because we don’t have many options after we use these up.

We offer an awesome program at Horizon Resources to keep track of your herbicide use and cropping history along with crop scouting, chemical recommendations for weed control and resistance management and variable rate fertilizer and seed application. I know growers pay upwards of $10 per acre for these services in other parts of the Northern plains, but we offer these services at no charge to our customers that are purchasing crop nutrients, seed, and crop protection products from Horizon Resources.

Some growers have a pretty good handle on managing crop rotations, herbicide resistance and record keeping, but others may welcome the help and can utilize our Agronomy staff for these tasks. It is not quite as simple as it used to be, and it all needs to work together to help all of us keep the herbicides available that we are using today working in the future.

As always, if you have questions, please ask!

John Salvevold, Agronomy Division Manager, CCA

To learn more about why some herbicides can be so persistent check out the latest episode of the Growing Pulse Crops podcast. Dr. Ian Burke, Washington State University weed scientist, breaks it down (pun intended) and explains the science behind herbicide carry over.

Early Planting Minimizes Root Rot in Peas and Lentils

It has been accepted as common knowledge for some time that to avoid disease with peas and lentils we should plant them into warm soils. While this might be true for cool season pathogens like Pythium and Rhizoctonia, the opposite is true for root rot caused by Aphanomyces and Fusarium. Fungicide seed treatments do a good job at controlling Pythium and Rhizoctonia, so we worry about those diseases less these days. Unfortunately the same cannot be said for our root rot pathogens, which thrive under warm soil conditions.Dr. Michael Wunsch and I conducted research from 2018-2020, which he has since carried on, to understand the interaction between soil temperature and root disease knowing that our most problematic pathogens grow best in warm soils. As a result, we now have a range of temperatures where we know we can reduce yield loss due to root rot.

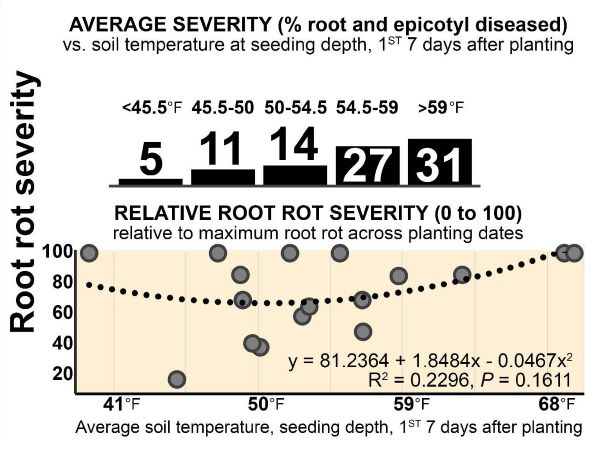

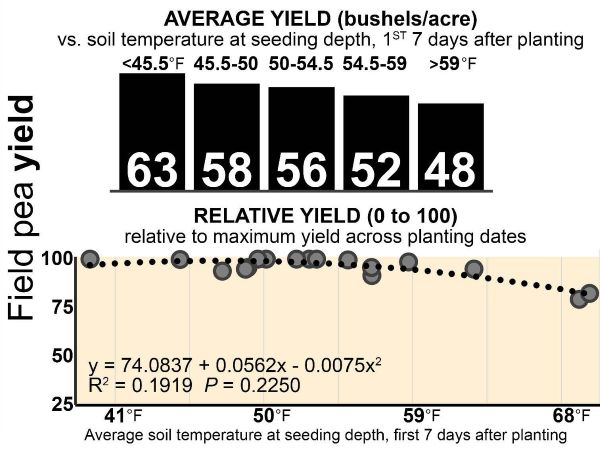

Below are results from five trials on field pea, where root rot and yield is plotted against soil temperature. Soil temperature was the average temperature at a soil depth of 2” in the seven days after planting. What you can see is that root rot was minimized at the lowest soil temperature (<45.5°F). Yield was also maximized when planting at this temperature.

Dr. Wunsch observed that planting much earlier than that resulted in frost damage and yield loss to the peas. An important note is that under these cool soil temps a yield response to seed treatment averaged around 5 bu./ac so if you do decide to plant early don’t skip the seed treat!

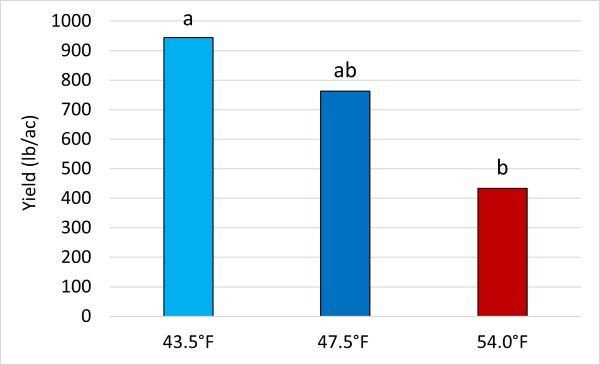

I observed the same trend when I conduced an on-farm lentil root rot study in 2020. This trial was located in a field with a history of disease in the Grenora area. The planting dates were April 24th, May 2nd, and May 13th and soil temperatures were recorded using buried soil temp data loggers. Yield drastically declined when soil temps were above 50°F and rising, and this corresponded to the increase in root rot observed with the later planting date.

NDAWN is a great resource when you are checking soil temperatures. Make sure you are looking at the daily average soil temperature, as surface soil temperatures can fluctuate greatly. The daily average soil temperature can be found under the weather data tab. You then select your location, turf or bare soil temp, and the date range you are interested in. It will give you a table that can be exported to an excel file. Below are the average bare soil temperatures from April 1st to April 13th at a 4” depth. Highlighted in the yellow box are soil temps in that ideal range of 43 to 50 degrees. If we want to target planting peas and lentils when the average soil temp in the seven days after planting is 43-50°F degrees then at some locations we are already within that window.

Again, when planting into cold soils we are at increased risk for our seed rot pathogens so check in with us about fungicide seed treatment options, which provide excellent control against those diseases. I discuss fungicide seed treatment in more detail in the On the Horizon podcast which you can check out on our YouTube channel or anywhere you get your podcasts.

Dr. Audrey Kalil, Agronomist & Outreach Coordinator

Kick-Start Your Week by Watching Your Delta-T!

As the season gets rolling—perhaps a bit sooner than usual thanks to a mild winter and an extra-dry spring—you might be noticing some unexpected weather quirks. I recently started keeping an eye on Delta- T values through NDAWN, and there’s a simple reason for it.What’s the Buzz About Delta-T?

In plain terms, Delta-T is the temperature difference between what you measure on a standard (dry bulb) thermometer and what you would see with a wet bulb (imagine it’s at 100% humidity). Experts in Australia and Western Canada have shown that when Delta-T is too high, up to 30% of your sprayed solution could vanish into thin air before it gets a chance to settle in the soil or reach your crop.For a clear, straightforward explanation, check out this insightful video by Rob Proulx, our very own NDSU Extension Agriculture Technology Systems Specialist: Watch the Video.

Why Should You Care?

With Delta-T readings changing every five minutes on the NDAWN website, you get real-time information that you can trust. I personally favor the map view because it gives a clear, geographical picture of where the dry air is—color-coded like a traffic light (Red for Stop, Yellow for Caution, and Green for Go).Not a fan of clicking through websites on the job? There’s also the “NDAWNInversion” app that connects with your closest NDAWN station, giving you an estimate right in your hand.

When Delta-T Says “Caution: Don’t Spray”

We’ve all been there—seeing a perfect day for spraying but then notic- ing the caution signal on your Delta-T monitor. Here’s what to do when you're facing those “don’t spray” conditions:- Upgrade Your Nozzles: Use nozzles that deliver larger droplets. They don’t evaporate as quickly, giving you a better chance to reach your target.

- Adjust Your Water Volume: Bigger droplets mean fewer of them overall, so increase your water volume to maintain good coverage.

- Smart Use of Adjuvants:Instead of the basic dry AMS, opt for something like Class Act NG. It includes AMS plus a surfactant that keeps droplets wet longer, ensuring more time for the spray to land and be absorbed by your plants.

Final Thoughts

While it’s always best to avoid spraying under high Delta-T conditions (remember, the red alert means stop), sometimes you must make the best of a tough situation. By regularly monitoring Delta-T and making a few adjustments, you can get the most out of each spray session— even on challenging days.Kyle Okke, Crop Consultant, CCA

Agile Agronomy LLC and Agronomists Happy Hour podcast

Introducing Zach Weiland: Horizon Resources Fairview Agronomist and Future Location Manager

I started my career in the U.S. Navy where I spent 7 years. After being discharged, I returned to my home state of South Dakota and began working for CHS at the local cooperative as an applicator. After a year in that role, I made the decision to return to college to complete my degree. During my summers, I interned with CHS as an Agronomy Trainee, gaining valuable hands-on experience.Upon earning my degree in AgriBusiness, with a minor in Crop Science, I was accepted into CHS's Manager Trainee Program. This program allowed me to gain in-depth knowledge of various aspects of the cooperative system by working closely with managers in the Grain, Agronomy, Feed, and Energy divisions. The program lasted one year and provided a well-rounded foundation in cooperative operations.

Following the completion of the program, I accepted a position with CHS in Brandon, SD, as a Precision Ag Specialist. My responsibilities included creating variable rate maps for fertilizer and seed applications, using soil, yield, and zone map data. During this time, I developed a strong interest in soil health and soil testing, as I observed positive changes in customer fields through tailored recommendations. In addition to my precision ag work, I was involved in chemical and fertilizer sales, warehouse operations, and fertilizer blending. Eventually, I transitioned out of precision ag and began focusing more on operations, aligning with my long-term goal of becoming a location manager.

In 2018, I made the move to Agriland FS, a division of Growmark, where I managed an agronomy facility in Missouri Valley, Iowa. There, I worked closely with my team, focusing on seed, liquid fertilizer, and anhydrous ammonia. Our location served as the primary seed treating facility for five branches, treating up to 50,000 units of soybean seed each season. Agriland FS is the largest user of anhydrous ammonia in the U.S., and our location handled upwards of 100,000 tons annually.

In August 2020, I returned to northwest Iowa and took on a management role with Cooperative Farmers Elevator (CFE) in Rock Rapids, IA. This was a larger, more diverse location encompassing agronomy, grain, and feed. I managed a team of 17 employees and oversaw operations that included cattle feed, grain receiving, and custom applications of both liquid and dry fertilizer and chemicals. During my time at CFE, I significantly expanded my knowledge in animal feed and its role in livestock health and sustainability. I also developed stronger relationships with customers through daily face-to- face interactions, which helped drive the success of the location. I grew my expertise on the grain side of the business, working closely with grain buyers and learning the ins and outs of grain contracts. Eventually, I began handling contracts for our location’s customers, ensuring they made informed and profitable decisions.

Now, as I begin my journey with Horizon Resources as the next manager of the Fairview location, I am excited to put my knowledge to good use and to get to know our member customers. I’m excited to be part of the Fairview location team, and I look forward to continuing to learn, grow, and make a positive impact in the community.

Zach Weiland, Agronomist/Fairview Location Manager

To learn more check out Episode 14 of season 2 of the On the Horizon podcast. Listen to the episode on YouTube or wherever you get your podcasts.